My plan to get us from Islay to Campbeltown in time for the Springbank tour was risky to the point of being stupid, a fact I downplayed when sharing the trip schedule with my wife. We had to get from Port Ellen to Springbank Distillery by 1pm; and we had all of a 30-45 minute buffer. Dozens of elements could have gone awry and made us miss our Springbank tour (and the other two connected tours for that day). The Islay ferry -- the vessel which delivers us to our hopes and dreams as per its whims -- could have arrived late, departed late, or taken too long. There could have been a problem loading or unloading the boat with its dozens of dopey tourists and their cars. One of a multitude of tractor trailers, which pin in the cars, could have stalled out. There could have been Scottish weather. The A83 could have had construction, car traffic, bike traffic, sheep traffic, or boulder traffic. And as I planned this trip three months in advance, I was unaware of a bonus factor: the impressively crap GPS that came with our rental car; worse than useless, it had gotten us lost plenty of times each day. So I was leaving a lot to chance.

You know who else leaves a lot to chance?

SPRINGBANK!

As you can tell by the photo above, we made it to Springbank. We arrived in Campbeltown in time, though the GPS led us in loops around town until we had to spot the Grammar Lodge B&B by eye. The lodge was in fact a grammar school many decades ago, and is now a very nice modern bed & breakfast. The friendly helpful owners were there to meet us and chatted us up a bit to the point that the little boy in my brain was hopping around like he had to pee saying "Springbank, Springbank, Springbank, Springbank, Springbank, Springbank".

The tour started at Cadenhead Whisky Shop, a quick three blocks away from the B&B. I made brief eye contact with the single cask bottlings that lined the walls, but elected to play hard to get because I had a date. His name was Mitch, and he was our tour guide. I say "our" because this was the day that Kristen was also attending all the tours. Which was awesome.

MALTINGS

Springbank has two malting floors. One has a 12 ton capacity, the other 10 tons. The floors are slanted, not for any technical advantages, rather because the building is old. All the barley turning is done by hand, not by machine, so it's only as precise as an overworked man hauling a heavy-ass shovel can make it. The malting takes place for six or seven days (judged by eye, not by math) at temperatures ranging from 16ºC-20ºC (61ºF-68ºF). The light is not controlled by lamps or timers, but by some dude (or dudette) opening the windows.

All of their barley comes from Scotland, usually the Highlands, usually the Concerto strain. When they do unpeated drying, they use hot oil. When doing peated drying, they first use dry peat from the Tomintoul region for heat and wet peat from Inverness for smoke.

|

| Dry peat from Tomintoul |

|

| Wet peat from Inverness |

|

| Useful data |

|

| NO computers, just lists and notepads |

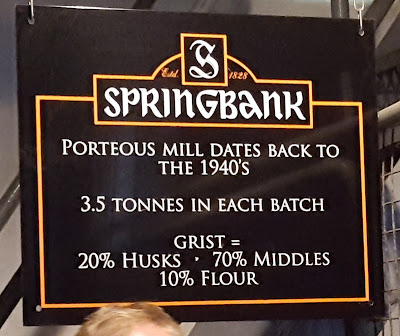

MILL, MASH, AND WASH

|

| Another one of these super sturdy mills from post-WWII |

While most distilleries use closed mash tuns to prevent stuff from floating down into their wort, Springbank uses an open mash tun which does allow for native yeast and other airborne microflora to enter the mix.

They do 3.5 ton batches in the tun using four different rounds of water, ranging from 63.5ºC-82ºC (146ºF-180ºF).

|

| Their washbacks are over 50 years old, but not without some recent servicing. |

Mitch told us they actually will do up to 110 hours of fermentation if necessary. This sort of length results in a very low ABV wash, lower than at most other distilleries. Apparently once Springbank's fermentation goes over 48 hours, the alcohol content begins decreasing rather than increasing.

DISTILLATION

Firstly, I apologize for the crap photo of their stills. Secondly, I don't remember if Mitch mentioned if Springbank still does partial direct firing. If they do, that's yet another element of potential inconsistency. Thirdly, here are the photos diagramming the distillation of the Springbank, Hazelburn, and Longrow spirits. I'll be danged if I can explain Springbank's 2.5x in a concise fashion:

|

| Longrow 2x (click to embiggen) |

|

| Springbank 2.5x (click to embiggen) |

|

| Hazelburn 3x (click to embiggen) |

THE WOOD

|

| Your eyes aren't deceiving you. This is not wood. It's the spirit receiver from which the spirit is poured into the casks. |

Mitch was excellent. I harassed him with questions throughout and he answered everything. There is no fear at the distillery that one of us is going to take this information and start fashioning Springbank in a bathtub. He told me the majority of their bourbon barrels come from Jim Beam and Jack Daniels. And they do not use virgin oak casks. They also rarely re-char their barrels, thus a refill is a refill.

THE BOTTLING

Their regular range bottlings are married in a big vat for 6 months at a starting strength of 50%abv. Meanwhile, their bottling facility, manned (and womynned) by locals, was located right on site near the vats:

We were encouraged to not enter the bottling area out of concern for someone getting a finger or other appendage lodged in the foil mechanism.

THE END, FOR TODAY

This distillery tour ended right here because another distillery tour was to immediately follow. The one theme I'd noticed throughout the tour is the one I keep coming back to in this post. Springbank, like an anti-Diageo or anti-Macallan, leaves a lot up to chance and thus embraces inconsistency (from the malting, to the wort, to the fermentation, to letting refill casks be refill casks). This results in a whisky that is never exactly the same from bottle to bottle, but is of a quality without compare in the industry. Now about that next tour...